PI: Prof. Deepak Kunzru

Co-PI: Prof. Goutam Deo

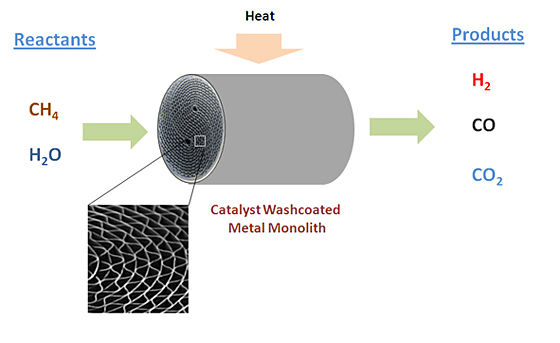

Steam reforming of methane on supported nickel catalyst pellets in fixed bed reactors is a well-established commercial process for producing CO and H2 but suffers from the disadvantage of poor catalyst utilization and heat transfer limitations. A potentially attractive alternative to overcome these limitations is to use metal monoliths coated with noble metal promoted nickel catalysts. In this study, steam reforming of methane will be investigated on metal monoliths coated with Rh or Pt promoted Ni/MgAl2O4 and the results compared with the data obtained on powdered catalysts in fixed bed reactors. The promoted catalysts will be thoroughly characterized to explain the promotional effect. For the most active and stable catalyst, the intrinsic kinetics will be determined and incorporated in a model for the monolith reactor. This reactor model will be used to determine the best heat integration strategy for carrying out this reaction on monoliths.